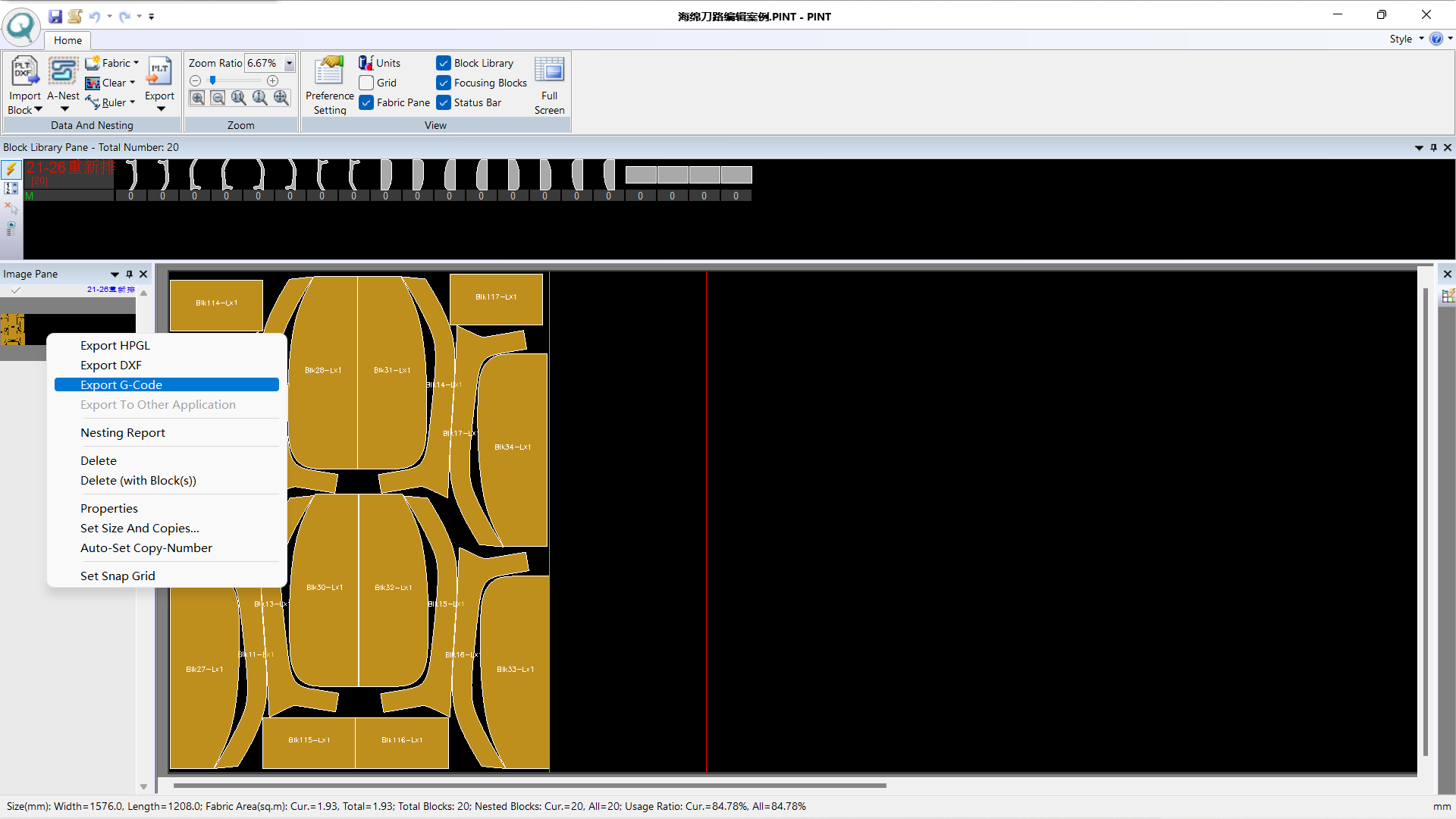

The software supports the import of DXF/PLT/CUT format pattern files, then can automatic or manual nest, while supporting the introduction of DXF/PLT/CUT format of the nest file, the formation of nesting can be generated G-CODE sponge cutting path.

At present , widely supporting the mainstream of the market ring knife, vibration knife CNC sponge cutting machine.

First, the realization of computer automation management, provincial processes to save time In strict accordance with the order quantity, the realization of any shape of the pattern in different rectangular materials on the automatic optimization of nesting, saving the tedious process.

Second, the production process, reduce the artificial dependence.

Realize automatic computer calculation, save time. The size of the row layout 2-10 seconds to produce the cutting knife path. Significantly reduce labor costs. Eliminate artificial drawbacks.

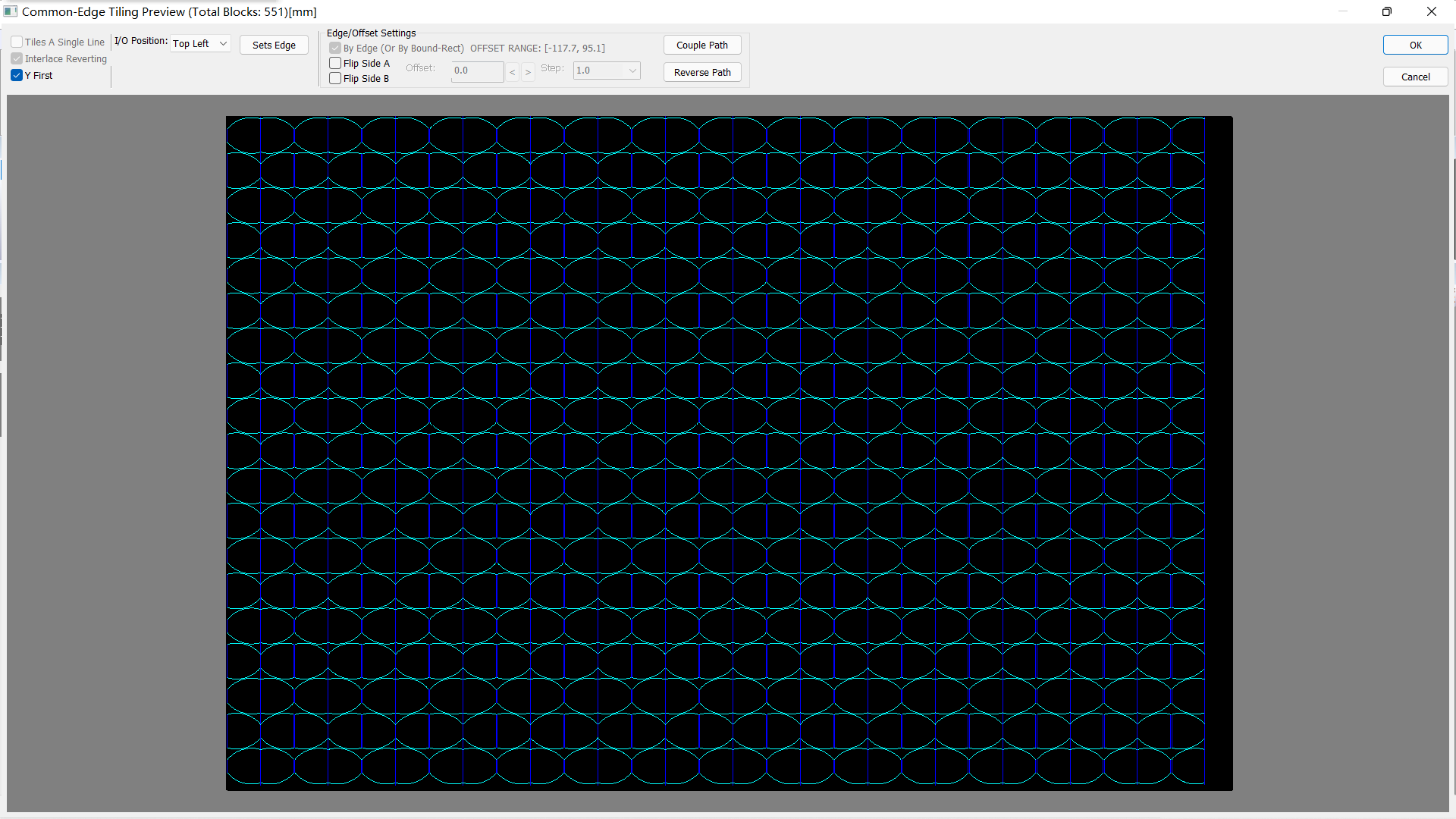

Third, have a variety of nest methods, a variety of cutting paths.

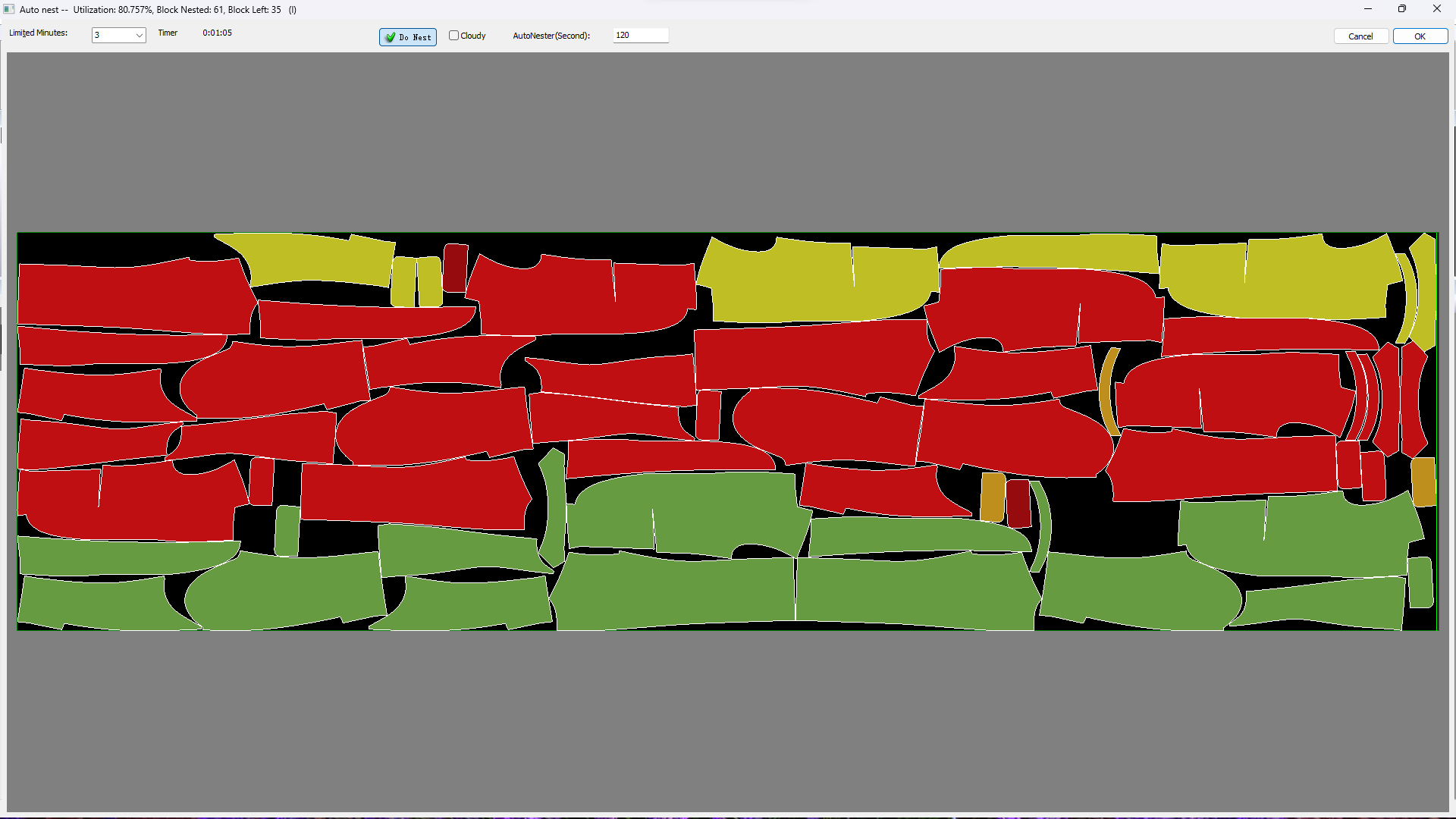

You can select one or more patterns that have been scanned and saved for nest, and you can choose from a variety of nest methods: Automatic mixing nesting, flat nesting version, Tile nest version, etc., you can also choose the selected pattern fixed the subsequent pattern automatic nest, you can set the pattern fixed direction: fixed angle or arbitrary rotation automatic row. Nesting reports can be generated: including utilization, information such as the amount of material nested from each pattern.

Nest reports can be generated: including utilization, information such as the amount of material nest from each pattern.

Iv. Support multiple rectangular fabrics nesting at the same time

In the case of computer performance permitting, multiple sponge materials can be used to calculate the nest.

Support grouping and layout according to each set, size or piece, and support grouping in both XY and single directions

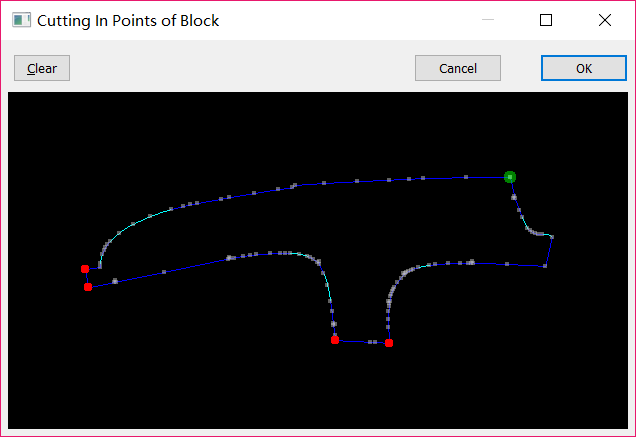

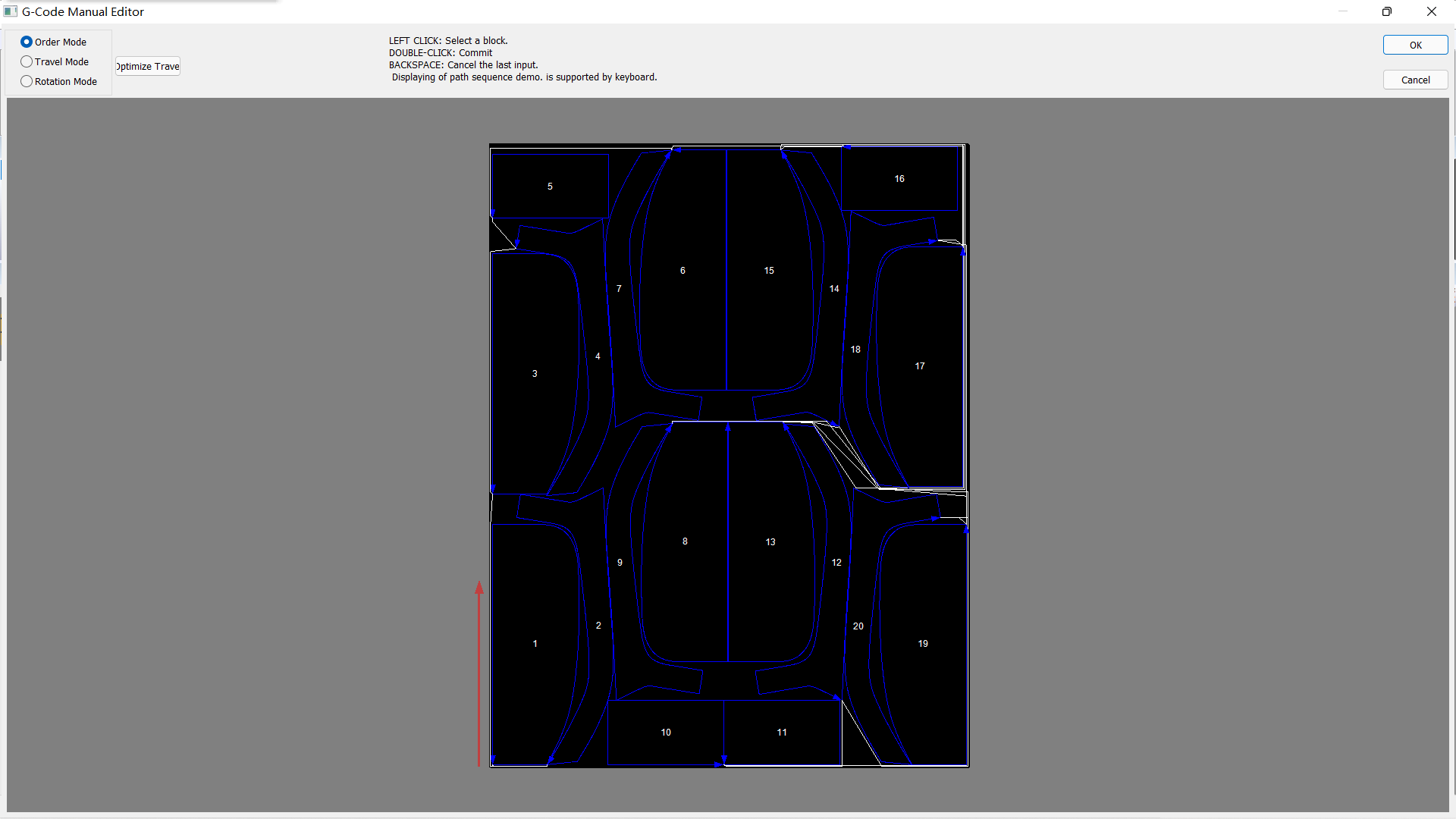

V. Manual control of the Knife road

Support model entry point setting, the whole nest drawing order adjustment, cutting path readjustment, cutting direction adjustment and so on.

Can cut rectangular array, rectangular size arbitrary input can be.

VI. output HMD/DXF/ISO/CNC data format The output passes include optimization algorithms such as cutting in turn, priority cutting in Y direction, and cutting nearby.

Support a variety of CNC ring knife, vibrating knife sponge cutting machine.

End