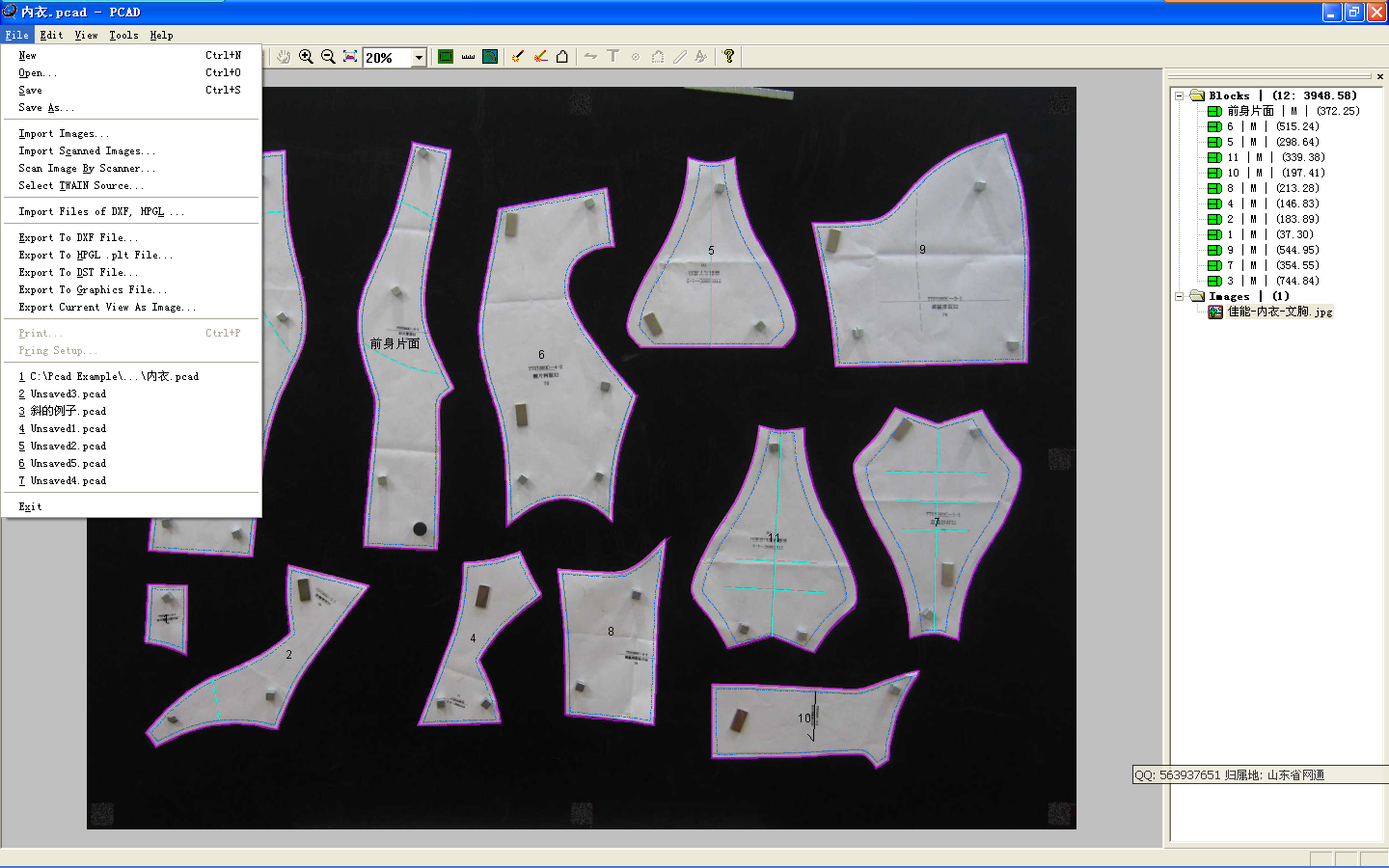

The software can analyzing and generate pattern automatically.

Now you can input the patterns to CAD faster. The DXF file can be used into gradding and design for three-dimensional by the software output. Also ,It can be used to quality control and verify the size. Software can measure slopwork, semi finished articles, the size, figure and angle of pattern nicely.

Through Digital Camera, you get the image file. Software analyzing and generate the pattern automatically and input it into PC , this brought the ultimate change to the pattern input tache. This improve efficiency greatly compare to tradition data device.

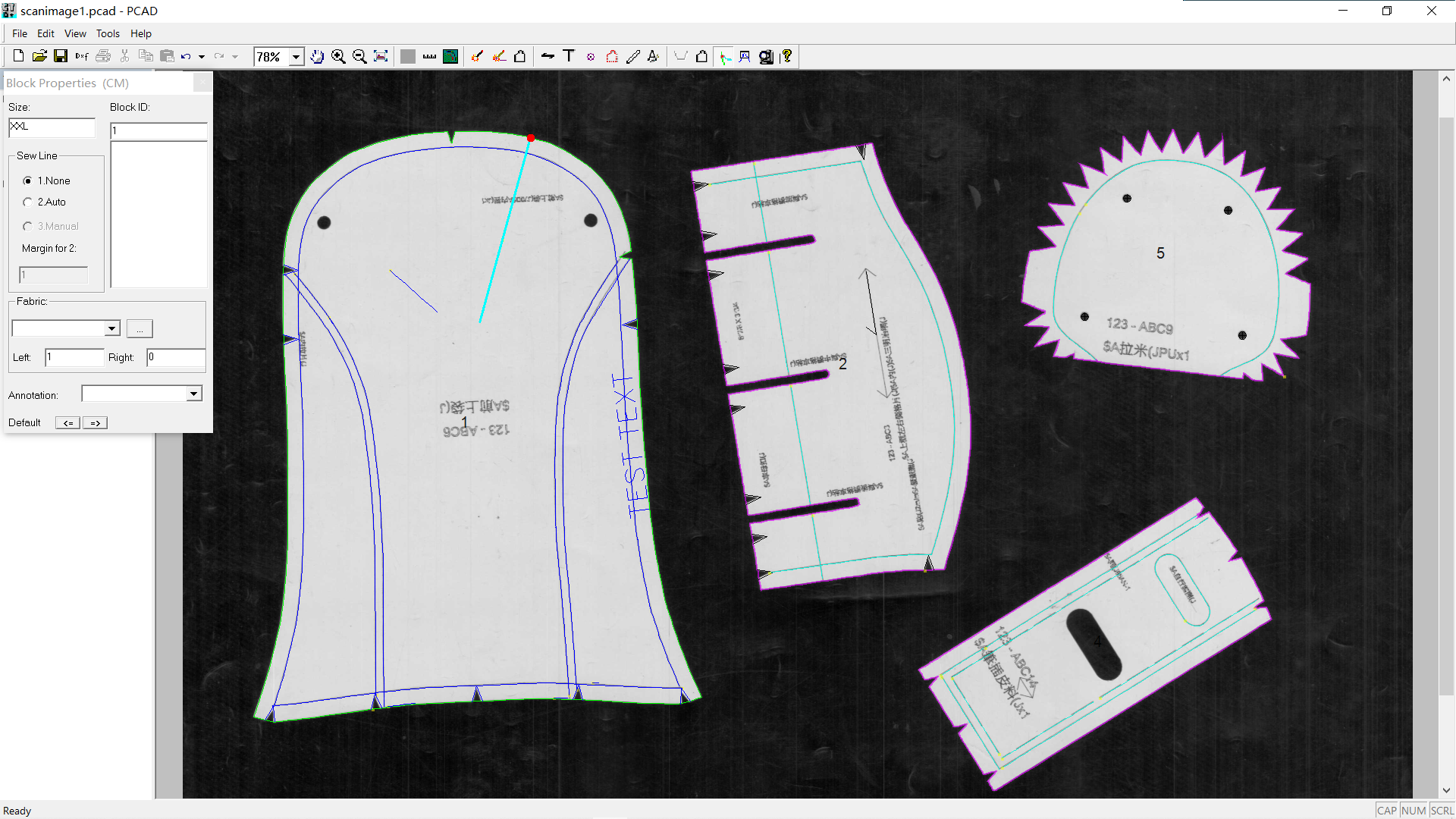

WYSWYG: software can judge the inosculation between former pattern and generation pattern, then mend, adjust,and error less than +/-1mm though screen. But digitize board, it must contrast and checkout the others after output pattern as pro rata 1:1.

Auto-generate seam and supply powerful edit tools

The seam can be selected when generate the pattern. The hemming-stitch’s width is adjustable by free.

Plain of pattern management:

This system provide document of PCD file-format, and save whole pattern and photogragh of same format and size for management.when having many pattern,this tool function of management is obvious.

Applying of DXF widely:

Whole pattern can save as AAMA-DXF( TIIP-DXF) format. It support by many sort of CAD and CAD of other industry.

Output to cutter or plotter – HPGL/PLT:

Software output the pattern to cutter and plotter and providing emendation of printer.

Connect to embroidery software - DST:

The software can output DST file. For embroidery software user, that input pattern as pro rata 1:1 omit the scann of pattern many times, assembling and any other complex course and improve your work efficiency greatly.

Operation interface of software: